Product Name:

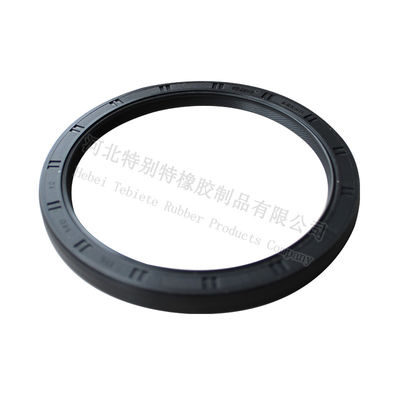

VG1500010047/1 SINO Truck Steyr Rear Crankshaft Oil Seal ,Weichai Crankshaft 115*140*12 Rubber Oil Seal

Material:

Product Details:

|

Product Name

|

SINO Truck Steyr Rear Crankshaft Oil Seal ,Weichai Crankshaft 115*140*12 Rubber Oil Seal

|

|

OEM

|

VG1500010047/1

|

|

Materials

|

NBR, HNBR, EPDM, SILICONE, , FLS, FFPM, PTFE

|

|

Temperature

|

NBR(-40~120°C),FFKM(-20~320°C)

(-20~200°C),Silicone (-70~220°C)

EPDM(-50~150°C),PU(-40~90°C)

|

|

Feature

|

Resistance to high pressure, oil, weather, abrasion, solvent, high temperature, abrasion resistant, aging resistant, insulation, acid and alkaline resistant

|

|

Certification

|

ISO 9001:2008

|

|

Hardness

|

30-90 shores A

|

|

Color

|

Red,Black,White, blue, green,Clear,etc

|

|

Size

|

Any size, Customized/standard and nonstandard

|

|

Sample Time

|

If in stock, within 3 days after payment

|

|

Delivery Time

|

10-20 days by shipping after final payment

|

|

Shipping

|

By Ships

|

|

Customized

|

OEM & ODM are welcomed

|

|

Packing

|

Plastic bag&carton box or according to your requirements

|

|

Certification

|

IATF 16949: 2016

|

Advantages of Natural Rubber:

1.NR also has excellent resilience, insulation, water resistance, plasticity and other characteristics, and after processing also has oil resistance, acid resistance, alkali resistance, wear resistance and other advantages;

2.Strong wear resistance, good shock absorption effect;

3.High elasticity, high tensile strength, excellent tear resistance and electrical insulation resistance Good abrasion and drought resistance, good processing, easy adhesion of other materials, It is superior to most synthetic rubber in comprehensive performance;

Installation Method

(1) Recommended oil seal installation tools and methods

1. The installation of the oil seal can be flush with the front end of the casing aperture, or it can be close to the low section of the casing aperture.

2. The reference planes for installation and positioning should be machined surfaces, and the unprocessed reference planes cannot be used.

3. The outer diameter of the oil seal should be coated with a layer of lubricant.

4, using hydraulic or pneumatic uniform pressure compression oil seal.

Note: The matching surface of the oil package is flush with the reference surface of the housing to ensure the verticality of the shaft and the center of the shaft after the shaft is installed, so that the oil seal lip becomes a line contact belt on the shaft surface to achieve a good sealing effect.

(2) Installation without oil seal

1.Apply a layer of suitable lubricant when the outer diameter of the oil seal is assembled

2. Tap the oil seal firmly and evenly.

3. Check that the oil package is flush with the reference surface of the casing after it is inserted.

Check that the oil seal spring must not come off.

Oil Seal Application:

The Engine

The Wheel Hub

The Gear

Construction Machinery Industry, Injection Molding Machine Industry, Metallurgical Industry, the Press Industry, Engine.

The Prerequisites of the Oil Seal on the Gathering Shaft:

1. The surface harshness of the shaft is as per the arrangements of GB1801. The shaft surface in contact with the oil seal should be ground to a surface harshness Ra0.2 ~ 0.63um and Rmax = 0.8 ~ 2.5um.

2. The width resistance of the shaft will not surpass h11 as per GB1801.

3. The chamfer width is as per GB13871-92.

4. Surface hardness: The material of the shaft is ideally carbon steel and composite steel. The suggested hardness is HRC45 or higher. At the point when the medium is filthy and has sullied pollutions from an external perspective or the direct speed of the shaft is ≥12m/s, the surface hardness of the shaft It should be HRC50 ~ 60, and the profundity of extinguishing layer should be ≥0.3mm.

5. The shaft is chamfered at 30 degrees (greatest). There should be no burrs, sharp corners, and winding handling blemishes on the chamfer. The unpleasantness of the chamfered surface Ra ≦ 3.2um. The warmth treated carbonized layer should be cleaned and eliminated.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!