Product Name:

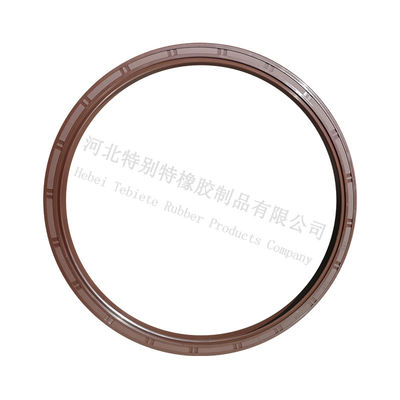

165*186*14 Oil Seal 3104045-A0A TC Type For FAW Truck

Material:

NBR

Raw Material and Equipments:

1. We have unique production technology and advanced production equipment;

2. Efficient and precise pre-forming machines have high production efficiency and high speed, meanwhile greatly reduce the waste of production raw materials, and are more efficient and energy-saving;

3. All oil seal vulcanizing machines use vacuum vulcanizing machines and composite molds, which truly achieve high efficiency, high environmental protection, low loss, low waste, and greatly reduce production costs;

4. Various series of products have quality testing equipment. After the completion of production research and development, fatigue testing experiments will be performed. Product quality is strictly controlled to allow substandard products to flow to the market.

5. Adhesive adopts German Lord's products, the world's first adhesive force, better quality stabilizer.

6. Use Taiwan imported rubber, first-class quality, wear-resistant, durable, high temperature resistance.

7. From raw materials to products, we strictly control every quality control.

Oil Seals Introduction:

Oil seals are used for automobile engines and geared motors, and are designed mainly to prevent oil leakage from the end of a rotating shaft, or dust intrusion from the outside air.

Oil seals serve to prevent the leakage not only of lubricants, but also water, chemicals, and gas from "gaps" in machinery. Oil seals also serve to prevent the intrusion of dust, soil and sand from the outside air.

Oil seals are indispensable sealing devices and are used in various fields, including automobiles, aircraft, boats and ships, railroad vehicles, construction machinery, farm machinery, petrochemical plants, and electrical home appliances.

Oil Seal Type:

TC, TB, SC, SB, TB5SY, VC, VB,VK ,TA, SA ,SAY,SCNY2,SCOT,SCOTPLUS

TCV, TCN, TCN-6, TZ TCHD, TCHD-1 ,ISPID, 15Z, 15Z-3,

TC4, TB4, DC, DB,DCY, HSCL,HTC ,HTC9L,HTGL,KC, VR, MG, CNB, SCJY, SCY, VK

Product Characteristics:

1. Speed: Mechanical movement speed is high, the lubrication oil film may be destroyed, because of not good lubrication and friction heating oil seal, cause life is greatly reduced, we use polyurethane or rubber oil seal at 0.03 m/s ~ 0.8 m/s speed within the scope of work is good.

2. The temperature: Low temperature will lower the elasticity of polyurethane or rubber seal, cause leaks, and even the entire oil seal becomes hard and brittle. High temperature can make oil seal volume expansion, soft, cause movement oil seal friction resistance increase rapidly and reduce the compression capacity. Suggest polyurethane or rubber oil seal work continuously - 10 ℃ ~ + 80 ℃ temperature range.

3. Should: Consider when pressure = "high pressure oil seal compression deformation, repellent extrusion ring, groove processing aspect also have special requirements. For get together ammoniac fat sealing the best working pressure in the range of 2.5 ~ 31.5 MPa.

4. Load: Oil cylinder can bear larger load, seal and bearing ring in a completely different role, suggest polyurethane sealing ring to ensure that the cylinder can bear larger load

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!